A Brief Company History |

|||

|

Waddington Electric was founded in 1956 by my grandfather. The company did machine and industrial wiring. Prior to this, he was an employee of Brown and Sharp, and had completed a full apprenticeship program there. My father ran the company from about 1962, when my grandfather decided to retire to Florida. We changed the name to Waddington Electronics in the 80s to better reflect the times. The bulk of our business concentrated on supplying custom CNC machine control panels to many of the machine tool builders in the southern New England area. We built our first roll feeds in 1984, outsourcing all of the machining. Now we have 30 employees in 2 buildings. The product line has expanded to over 60 models and sizes of roll feeds, and we have 6 different stock straighteners. One of our buildings houses our main offices, electronic assembly, and machine testing. The other building is the machine shop. Almost all of our machined parts are done on CNC machining centers and CNC lathes. This allows us to adhere to the extremely tight tolerances required to build precision feeding and straightening equipment. Our electrical and electronics department have supplied controls and control panels to nearly every OEM in the metal stamping industry. A few of them include: Rowe, Rapid Air, PA industries, Sesco, Coe, Dallas, Litell, Rapid Air, Jaybird, Press Room Equipment, Perfecto, American Steel Line, Production Machinery, and Wean United. In addition, our EZ circuit products are used throughout the world by control panel builders and control systems integrators such as: Allen-Bradley, Rockwell, Reliance, Unico, General Electric, and Cleveland Machine Controls. We also manufacture loop controls of all types, and have sold over 60,000 of our very popular Sona-Trol non-contact, ultrasonic loop control. |

||

Machine Shop and Office/ final Assembly |

|||

|

|||

Sona-Trol and panel shop assembly area |

|||

|

|||

Roll Feed Testing area |

|||

|

|||

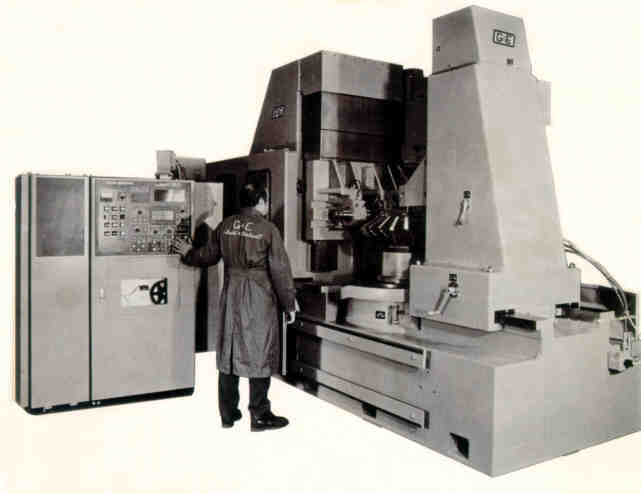

Machining center |

|||

|

|||

Waddington Electronics Inc.

office (401) 781-3904

fax (401) 781-1650