KAS SERIES CONTROLS |

|||

|

|||

single or Multi AxisBuilding on the sucess of the AKD single axis systems this multi

axis system is cost effective for jobs where there are many feeds on

1 line. Programming is easy and is done through a NEMA-4 touch screen. 110, 230 or 460 v operation. High powered control can have remote operator station. |

|

||

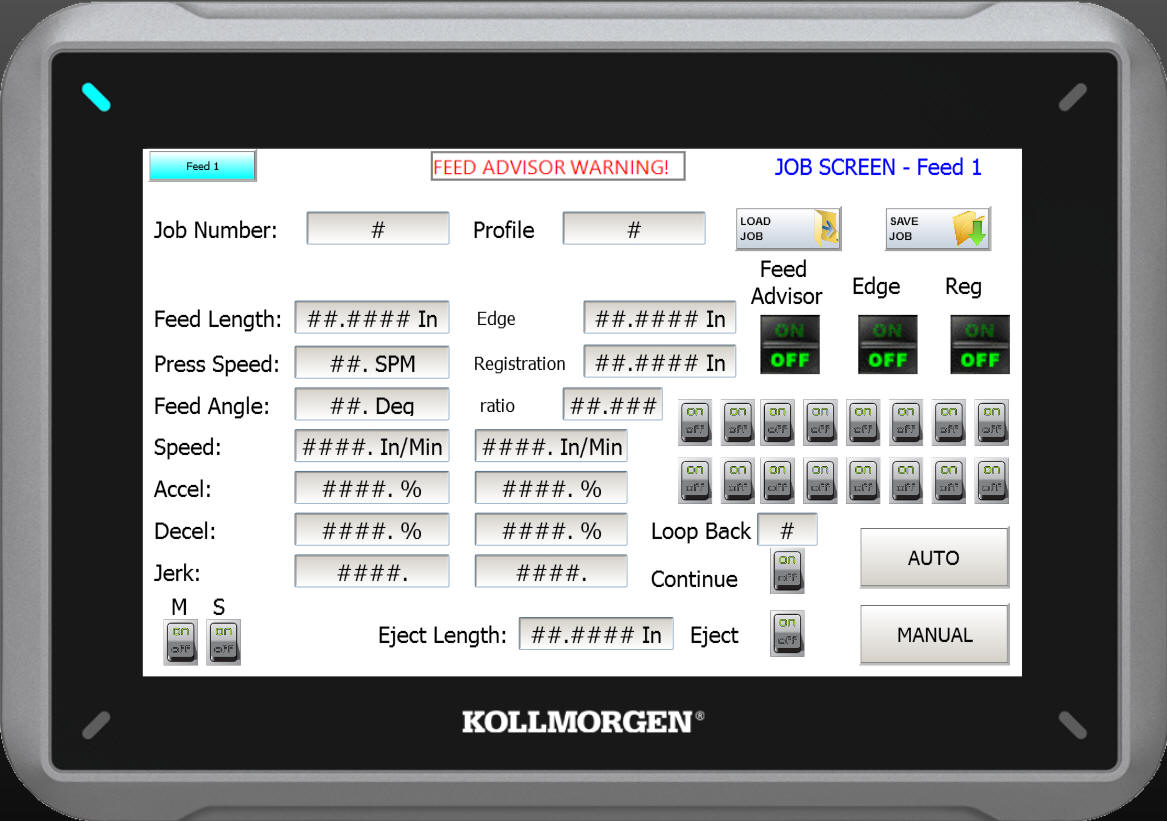

Programing features include Indexing |

|

||

| Proven Performers |

Waddington roll feeds are proven performers in industrial applications. They offer easy to understand programming and setup and unparalleled accuracy. Their Brushless motor technology and sealed bearings offer near-zero maintenance and microprocessor controls provide for fast, easy, and accurate length control to complement "just in time" and "quick die change operations." Several control console arrangements are available to suit various pressroom space considerations, and five feed body variations allow selection of feed size to suit budget, performance, and capacity requirements. |

||

| Increase Production | With indexing rates as high as 1500 spm (strokes per minute) our feeds have the fastest production rates in the industry; and, we can size the proper servo drive for your custom application using computer simulations of your stamping specifications. Production rates can increase as much as 300%. | ||

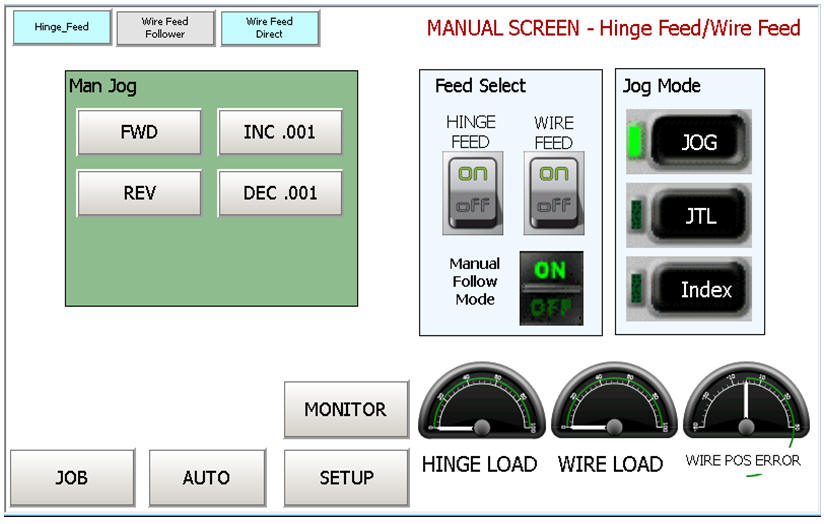

| Quick Setup | Touch screen control of feed length, speed and acceleration are provided and stock can be manually threaded and positioned in the tool using the remote jogging control station. | ||

| Accurate Positioning (in either direction) | Accuracy in roll and bearing journal grinding and dowel-pinned heavy-duty feed frames are only part of the reason PRF feeds provide exceptional positioning performance. High bandwidth servo systems, zero backlash drive train, and high resolution high accuracy feedback provide for robust servo performance in the face of varying load conditions. | ||

| Big Performance in a Small Package | Compact, direct-coupled over and

under-driven feeds fit in the same space as mechanical feeds. They

also have the added benefit of being locatable on any side of the

press because they require no mechanical linkage to the press crank

shaft. The LD series provides incredible indexing performance for

light duty applications and fit on both small and large presses, and

in tight spots too small for other feeds.Electronic cam switches and die protection systems can be integrated in the feed package. |

||

| High-speed Air-operated Pilot Release |

High Speed Air Pilot Release APR-3 Waddington Electronics has developed air pilot release mechanisms that operate at speeds up to 300 SPM. APR-3 allows fast pilot travel adjustment allowing you to optimize pilot release travel and maximize production. Cylinders can be fitted with optional sensors for easy monitoring in critical situations. Included feed software let you turn your

laptop into a scope to perfectly dial in pilot timing or

other press or feed signals. |

|

|

| Punch Press Shock Immunity and Resistance to Electrical Noise |

Our new state of the art feedback devices are the most noise immune and shock resistant way to get position information from the feed to the positioning system. Waddington Electronics Builds feeders in over 60 variations and sizes, and we will custom build feeds to suite your needs. Feeds are listed by series SF to HD and then By special Application in general any of our feeds can be configured for any of the special applications. We also offer many options and accessories to customize the feed to your application and if you don't see what you want just ask. |

||