ND Direct Drive |

|||

|

|||

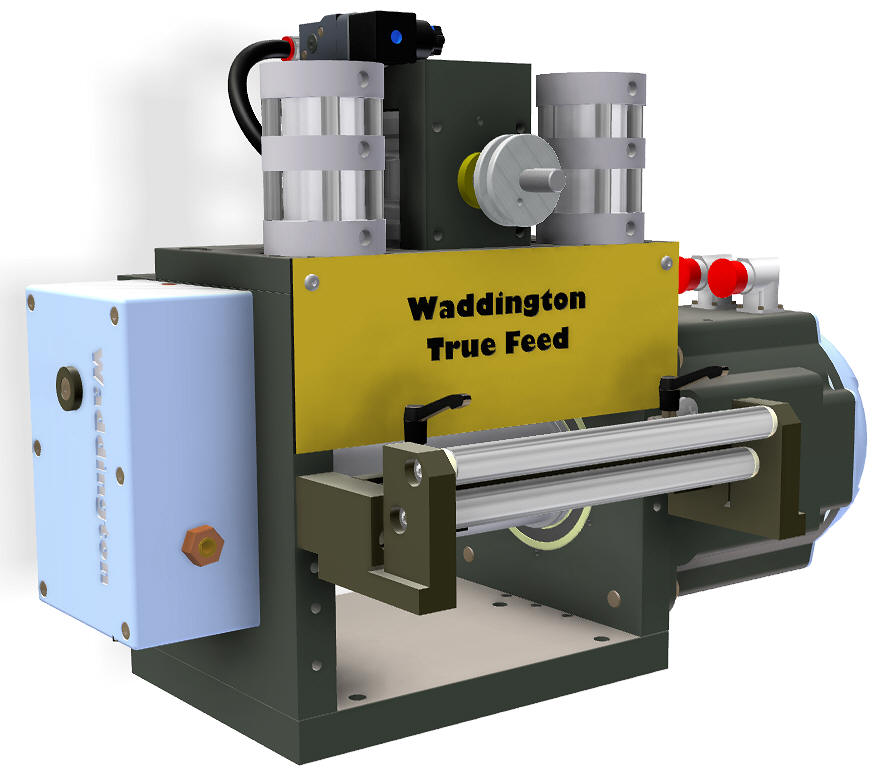

| Very accurate +-.0005 | Zero backlash and compliance provides more responsive system performance Integral feedback provides resolution of over 2 million counts per revolution Direct load connection eliminates maintenance of gearboxes, belts, or pulleys Reduced number of components. no belts and pulleys Gearing in oil with full thickness range without any adjustments. Gears remain fully engaged through the entire feed thickness range. New controls feature touch screen user interface. CE compliant options for global acceptance |

||

| Basic specifications: | Maximum Stock Width Up to

30 inches Maximum Stock Thickness .1875 inches Minimum Feed Length .000 inches Maximum Feed Length 1200.0000 inches Standard Accuracy +/-.0005 inches Power Supply (see options) 230V or 460V 1 and 3ph 60hz |

||

| Mechanical Features: |

Three-inch diameter smooth steel finish rolls Our special low inertia

roll design is proven performer in thousands of applications. Gears run in oil Two adjustable stock entry guides Cam rollers with handles. No tools

are required for adjustment. |

||

| Electrical Features: | |||