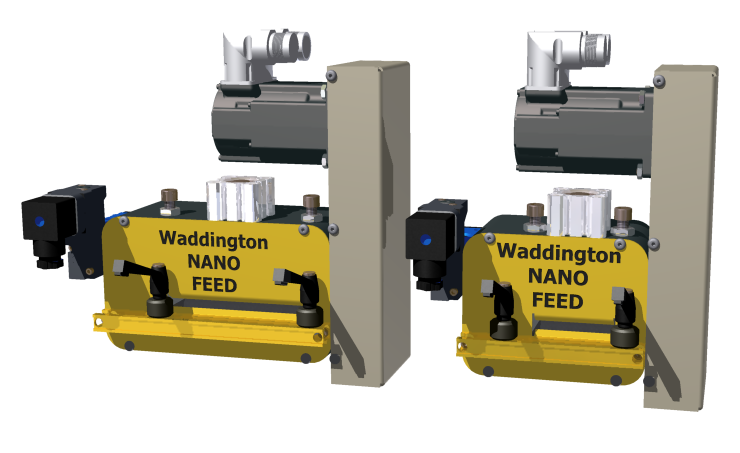

Waddington NANO Feed |

||

Much more than a low cost air feed replacement |

||

|

|

||

SpecificationsMaximum Stock Width 2

or 4 inches Standard Accuracy +/-

.001" |

|

|

The PRF NANO feed features the following:

|

||

Mechanical Features:Smooth steel finish rolls. Precision long life Kevlar timing belt Less elastic than steel, Kevlar belts are the ultimate choice for speed reduction in servo systems. We warranty the belt for 10 years. Air pilot release: Used for releasing the feed rolls, allowing pilot pins to take control of strip position, or to help compensate for defects in strip geometry. Waddington feeds feature one of the fastest air pilot release systems in use today. |

|

|

Electrical Features

Motor Connectors Only the highest quality motor and feedback connectors are used to insure reliability. Electrical surge suppressers 6 suppressers

are provided to suppress any inductive coils found in the press

electrical control system. Additional suppressers are listed under

optional equipment. |

||

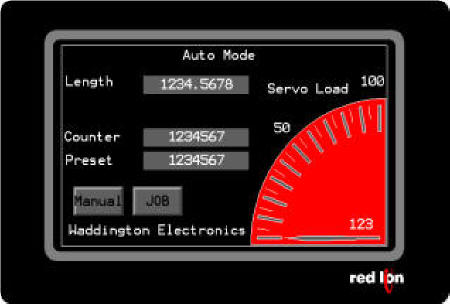

Operator InterfaceIndustrial touch screen |

|

|

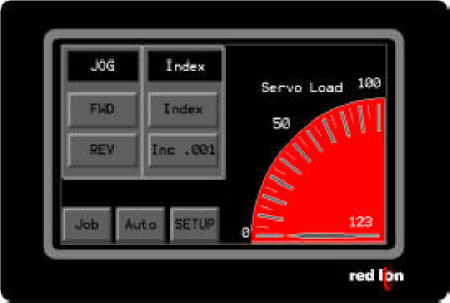

Productivity FeaturesData EntryWaddington feeds come with a IP-66-rated (oil, water, and

dust-tight) industrial touch screen. Changing the feed parameters,

such as length, speed, and acceleration, is fast and simple. JogThe jog feature allows the press operator or setup person to jog the material through the die. When used in conjunction with jog-to-length feature, the material can be jogged up to stock guides started in the guides, and then continued into the next die station, the jog-to-length software will automatically stop the feed at exactly the proper location. This feature allows for rapid threading of progressive tooling with stock lifters or unsupported areas between die stations. |

|

|

Electrical /Pneumatic roll open/close operation For easy stock threading into feed rolls. |

|

|

Electrical I/ORegistration input for precision location of printed or

prefinished stock. Fault Signals other equipment in event of feed overload or

failure |

||

Control Console:

Each feed ships with one set of D-Sized electrical drawings, an installation guide, an operator’s manual with programming instructions, examples and a trouble-shooting guide. In addition, factory manuals are provided for the positioning system and servo drive. All systems are followed by our computerized feed tracking database; all major feed components are tracked by serial number. This computerized system allows our service and support staff to provide prompt answers to your servo feed application questions and service requests.

|

|

|

OPTIONAL EQUIPMENT:Stock entry and control options |

||

Feed Mounting optionsMini mount 5/8 adjustment |

|

|

|

Heavy-duty Adjustable Mounting Bracket: Heavy-duty Adjustable Mounting Bracket: |

||

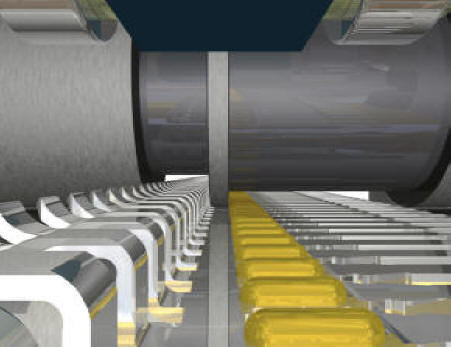

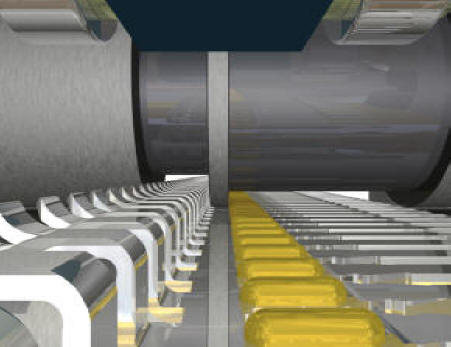

Special RollsSLC series feeds come standard with smooth rolls. Matte Chrome feeds rolls are grit blasted and then finished with industrial chrome. Matte Chrome Finish Profiled rolls Brand name finishes such as Kroton are also available but are basically the same composition. Chrome plated rolls provide excellent roll wear characteristics and the rougher finish provides improved traction between the rolls and the stock preventing material slippage during high acceleration. Smooth rolls work best with Prepainted materials and are also sometimes used to prevent material marking on some materials. Matte chrome is used in most general stamping operations

and when increased gripping force is required |

|

|