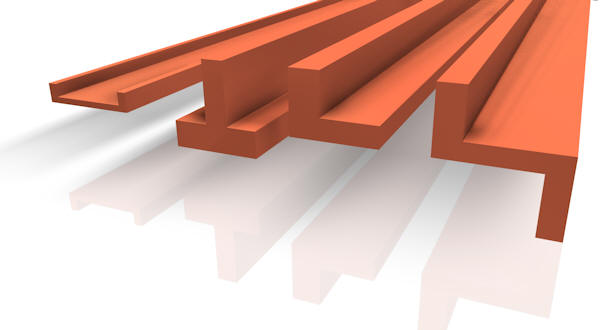

Cut Strip Feeds |

Feeds for pre cut lengths or materials that don't come in coil form.Some examples include I T L and Z shaped materials. |

||

|

|

||

|

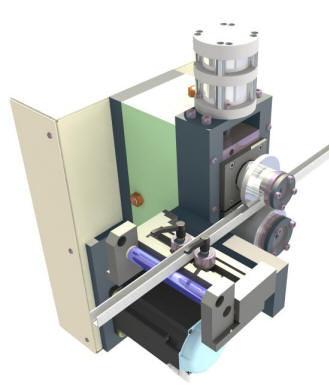

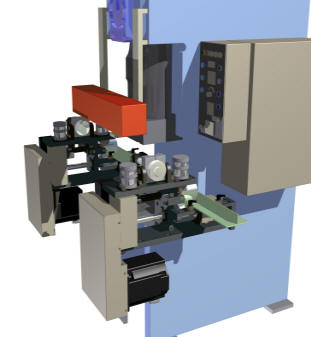

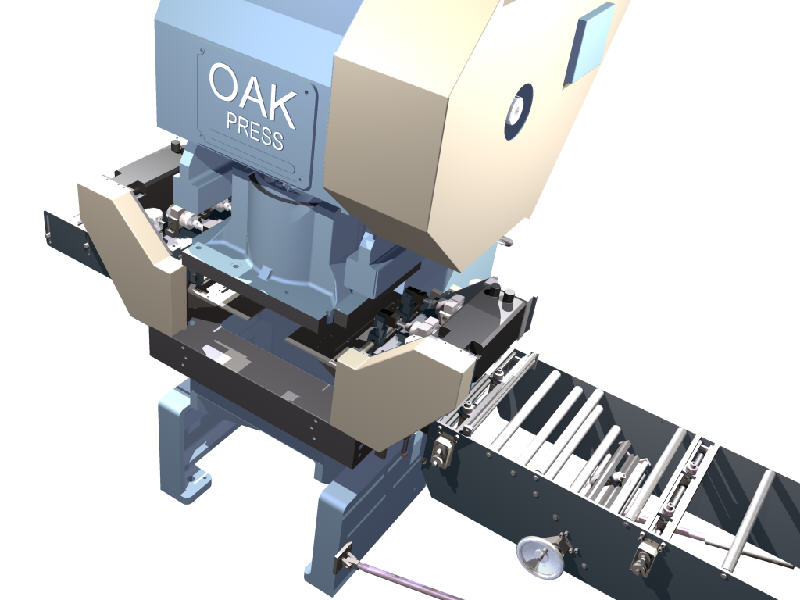

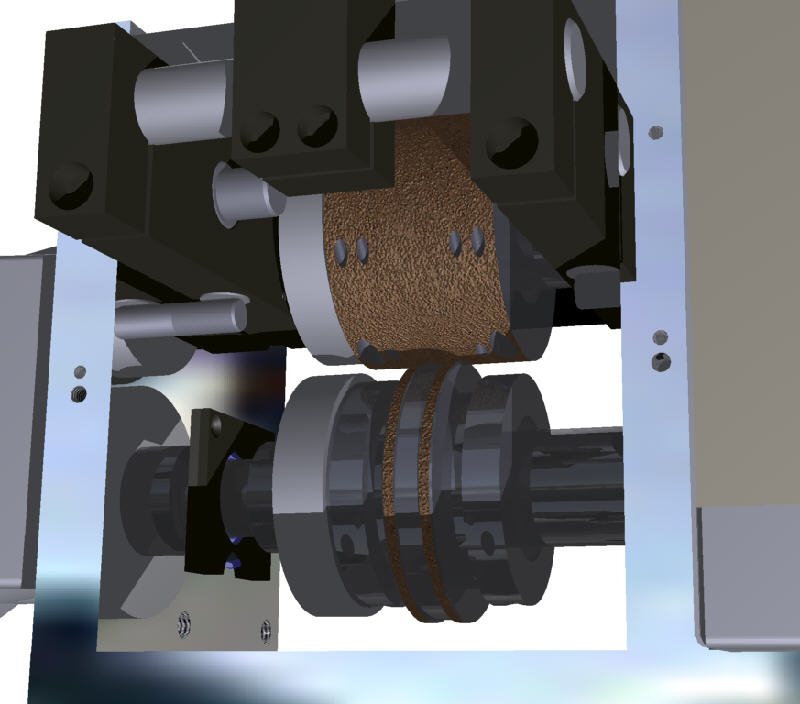

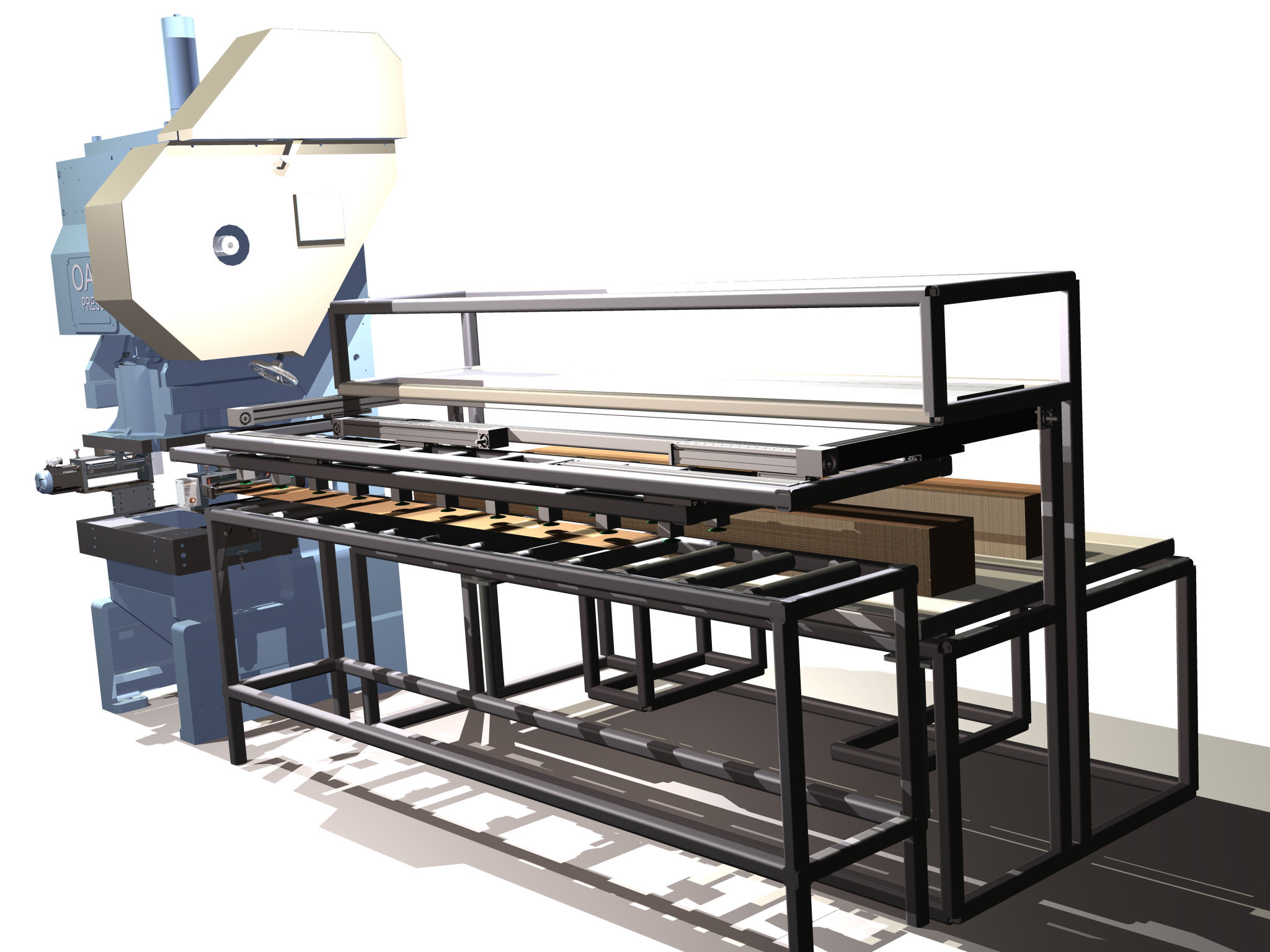

Push Pull Feed system configured such that operator or robot can start material between the feed rolls. At the signal of the operator or a strip loader the feed rolls will close on material, feed to a sensor to accurately locate the leading edge of the strip, then feed from sensor to 1st die station. The feed will index the part through the die station until such time as the output feed can takeover. Additional registration moves can be performed while punching to insure proper registration to preprinted or pre punched features. The output feed (pull feed) will continue feeding the part until the part is complete and then execute a long feed to eject the strip while the in feed is queuing up the next strip and can have it in position between press strokes to allow the press to run cut strips in a continuous run mode. Custom rolls can be designed and built to feed formed strips such as L's and U shaped Channels |

|

||

|

|||

|

|||

|

|||

| Strip loading robots can be interfaced for automatic loading. |

|

||