Waddington has developed Feed control software specifically for multi Slide applications.

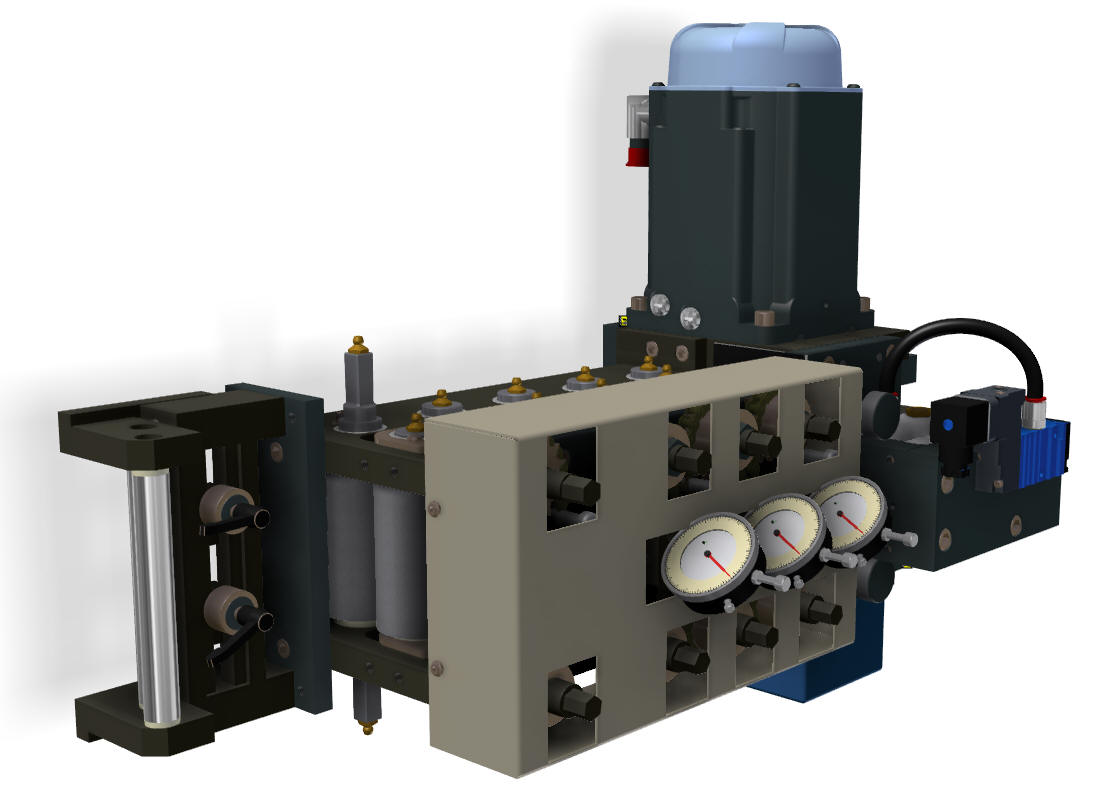

This feed was mounted on a Baird #33

Feed setup time was reduced from hours to seconds

Simple indexing or optional cam position mode operation

Waddington Electronics has developed a software package for its line of servo driven roll feeds that benefits users of Multi-Slide machines and Link motion presses with transfer die systems.

The Major feature of this software is :

Cam position Mode

The strip position is slaved to the machine position, The feed behaves the same as a mechanical cam feeder. A job is entered as FEED LENGTH, START ANGLE, and DEGREES OF FEED TIME. This mode requires an external resolver coupled to the crankshaft of the machine. And a top of stroke sensor or contact closure. These signals can be supplied by existing Data Instruments (Or Equivalent ) cam switch or die-protection systems. Or by the optional resolver and proximity switch.

Some manufactures are using this feed to increase the available forming time on Multi slide machines. This increase in forming time allows forming slide cams to be designed with longer lift angles thus reducing slide acceleration on long travel form tools. This then allows them to increase the overall machine parts per minuet rates due to the less radical cam lifts required.

One Manufacturers measured their return on investment at 75 days. And an increase in profits of over $ 35,000.00 per machine over the 1st year of operation.

Others are using this system to synchronize the feed with in die part transfer systems. This allows the feed up portion of the cycle to remain perfectly timed to the transfer mechanism. And will even reverse the stock feed when the machine is backed up.

Cam motion also simplifies Die Protection because the strip position is linked to the press motion and checking angles remain constant regardless of press speed.

Other Feed Modes are also available and are very useful during Setup and running some jobs.

Manual Index mode Completes feed progression when button is pushed.

Jog To length Mode Useful for threading dies with stock lifters and enclosed guide sections.

These signals can be supplied by existing Data Instruments (Or Equivalent ) cam switch or die-protection systems. Or by the included resolver and proximity switch.