Pilot Release |

||||

| We

Offer Mechanical Air Operated Belt Driven Cam Servo Pilot |

||||

APR-3 The fastest Air pilot release you can buy |

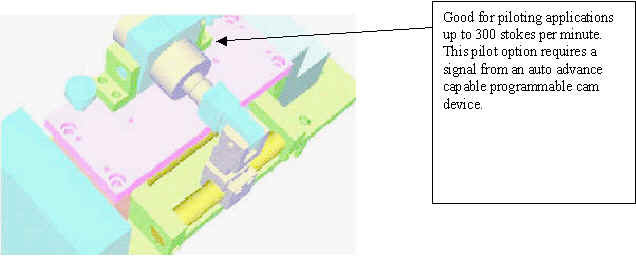

High Speed Air Pilot Release APR-3 Waddington Electronics has developed air pilot release mechanisms that operate at speeds up to 300 SPM. APR-3 allows fast pilot travel adjustment allowing you to optimize pilot release travel and maximize production. Cylinders can be fitted with optional sensors for easy monitoring in critical situations. Included feed software let you turn your

laptop into a scope to perfectly dial in pilot timing or

other press or feed signals. |

|||

| Auto advance cam capability once programmed for the particular job enables the timing of the cam signal to be advanced or retarded to match changes in the operating speed on variable speed presses. The auto advance feature is necessary on presses that have speeds of several hundred strokes per minute. This is accomplished in the programmable controlled cam device. Such programmable cam devices that have this feature are the Wintriss SmartPac unit with ProCamPac option or the ProCam 1500 and many others. |

|

|||

| Servo Pilot Uses a servo motor to drive a rotary cam | This is allows extremely high speeds without any connection to the press crank shaft | |||

| Requires top of stroke signal from press cam switch. Benefits of this piloting method are that it is saved as part of the servo feeders job specific data, repeatable from job to job, easily modified in the control, very accurate, does not require an auto advance capable programmable cam device, and can handle press speeds up to 1500 strokes per minute. | ||||

|

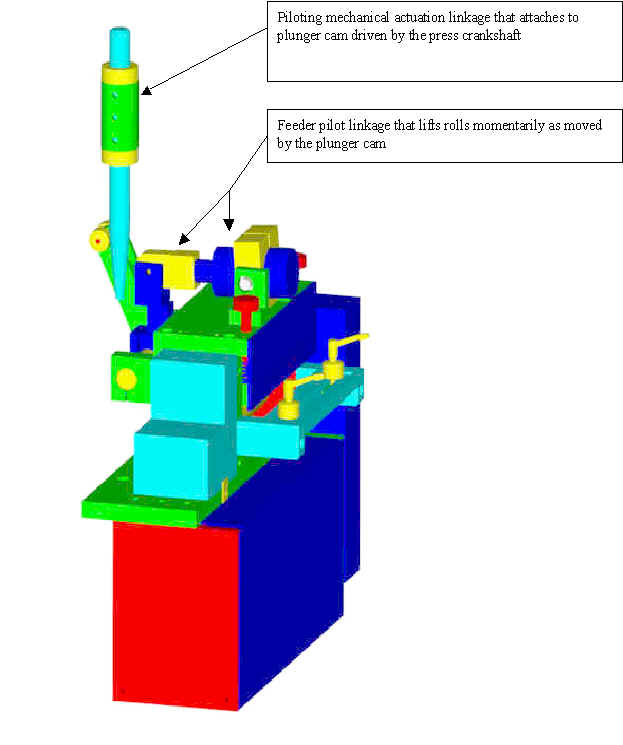

Mechanical pilot release Waddington servo feeder mechanical pilot release mechanism that is actuated off a plunger cam attachment to the press crankshaft Draw back to this piloting actuation method is that it is difficult to accurately repeat a pilot timing signal from one setup to the next. It involves much trial and error to establish the timing as it is manually adjusted at an attachment to the press crankshaft. Also it is difficult to use, especially on a straightside press, since the press crankshaft has to be readily accessible for both attachment of the pilot actuation mechanism and its adjustment. This method will work fine should your process be dedicated and requires few modifications to the setup from one job to the next.

|

|

|||

t

This page by Eric Easterday of Press Automation