Welcome to our webbsite. We are under construction . If there is something you need please call us at 401-781-3904

High

Speed Precision Straightening

High

Speed Precision Straightening

Stress relieves material

Great for motor and transformer laminations

All Rolls Driven

Easy Bank Adjustment

all rolls backed up

1.25 and 2" diameter rolls

3" pinch rolls

coil and parts straightening

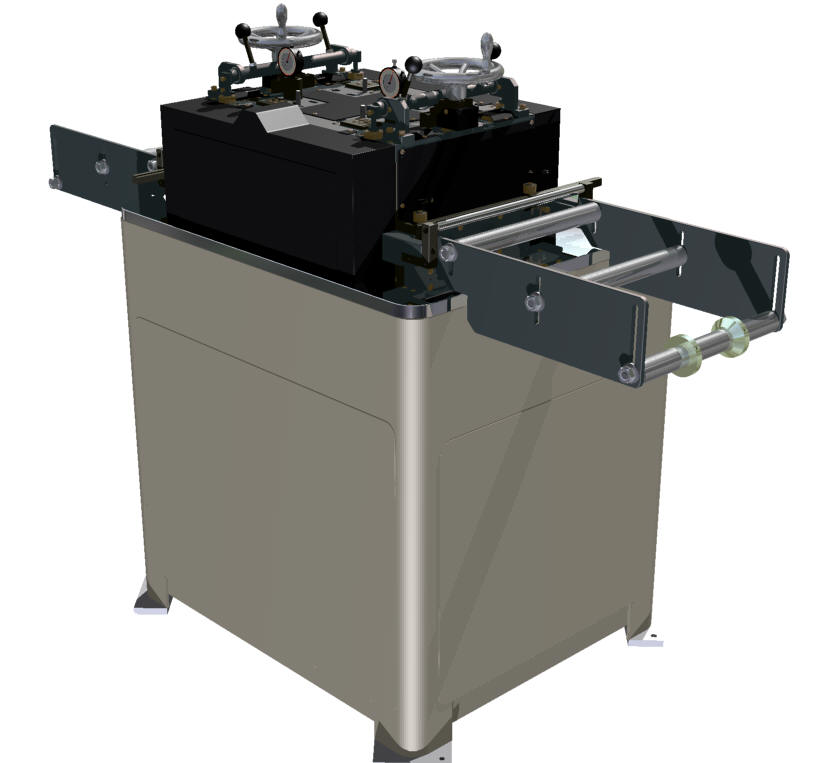

Precision Stock Straighteners

Designed to complement today’s high speed Servo driven roll feeds,

Waddington PSS high performance Precision Stock Straighteners

deliver easy setup and superior straightening capabilities.

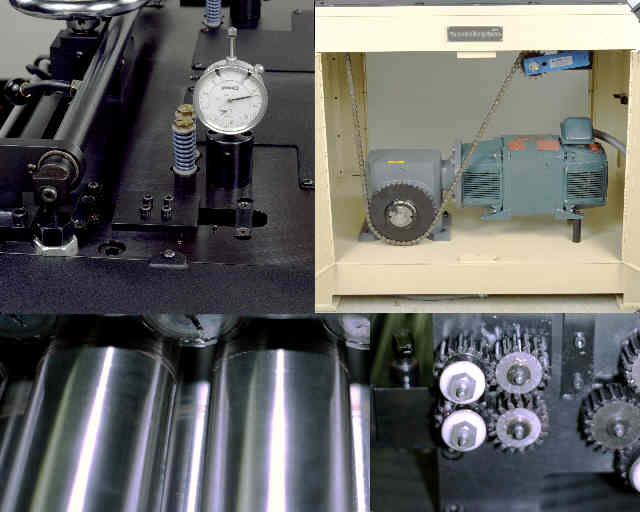

Setup is fast, easy, accurate, and repeatable. Upper roll bank

adjustments are made simply by turning hand wheels located at the

entry and exit sides of the machine. Dial indicators allow precise

settings to be accurately repeated so that valuable time is not

wasted with trial and error adjustments associated with lesser

equipment.

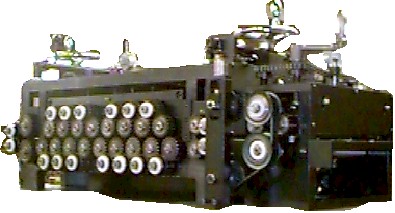

With its 21 rolls this Straightener eliminates problems associated

with coil set variation from the start to the end of the coil or

changes occurring when switching from running off the top or bottom

of the coil. This precision stock straightening machine will deliver

flat stock to your feeder faster and flatter than any 5, 7, 11, or

17, roll machine on the market.

The large numbers of straightening rolls allow a gentler, gradual

straightening of the material and the unified upper roll bed design

allows for easy setup and adjustment of the straightening process.

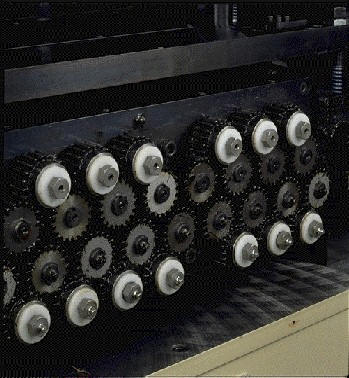

All straightening rolls are backed up to minimize roll deflection

this allows the material to be heavily worked without imparting

distortion into the length and width of the material.

21 2inch diameter roll with Down set option

Electrical controls include High performance DC and optional AC

drive systems and Non-contact Ultrasonic loop controls are standard.

The drive system is designed to provide a smooth continuos flow of

material to the feeder. The control system is designed to eliminate

material dragging across the floor and provide smooth non stop

material delivery to the feeder loop over the its wide range line

speed capability.

When combined with today’s high speed presses and feeders the

superior features of the PSS Straighteners allow higher levels of

production, quality, die life and profitability.

Standard Features Include

DC Regen Drive Package; including:

SONA-TROL control and start / stop / jog forward / jog

reverse/ auto / manual selector switch and remote push buttons for

jogging on a coil cord in a NEMA 12 enclosure.

Dial Indicators

Continuous running with no set marks

One piece hardened and ground rolls .0002 TIR

All rolls positively powered

All rolls backed UP

Three inch entrance and two inch exit powered pinch rolls

Precision Roller bearings on all rolls

Controls include forward / reverse and remote JOG

Hardened Drive Gears

183 ft / minute max operating speed

Ground Heavy duty side plates and bearing blocks

Rugged steel machine base with ground top

Key Benefits

- Reduce mis-feeds

- Stress Relieves material

- Increase up time and die life