Pull Thru Straighteners |

||

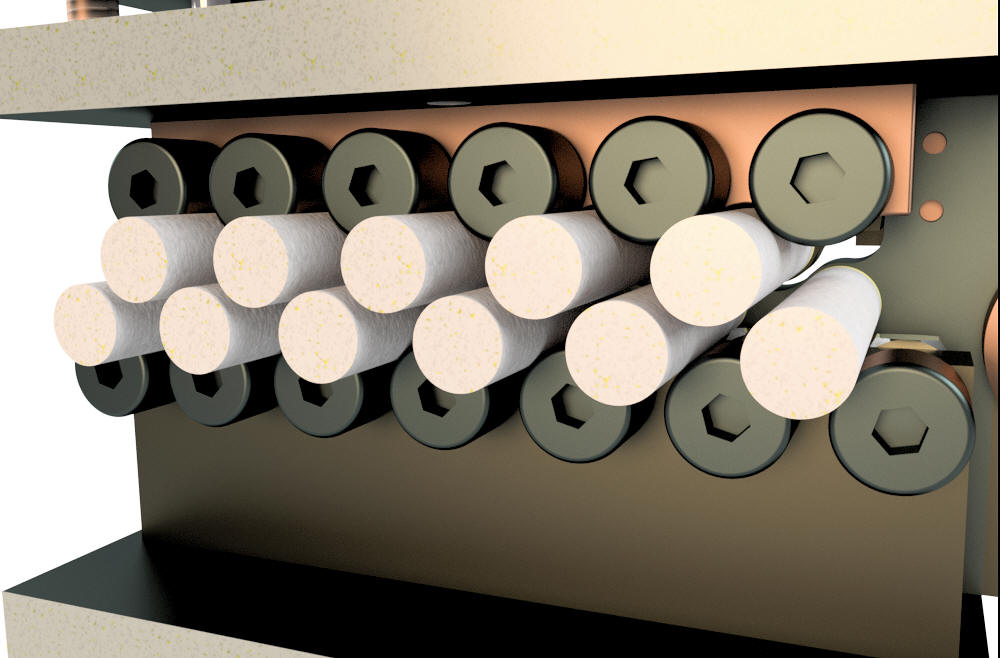

High quality precision built pull through Straightener's5, 7, or 9, straightening rolls 1/4, 3/8, 1.25, 2, 3, 4 inch diameter rolls Small diameter backed up versions Machines from 1" to 48" wide Custom machines Convex and Concave rolls |

Straighteners work by repeatedly bending the material beyond

its yield point thus elongating the faces of the strip to

make them equal Roll diameter required for the job depends on the material thickness and yield strength.  Thinner materials require smaller diameters to effectively straighten the material. More elastic materials such as some aluminum alloys also require smaller rolls and can be difficult to straighten. |

|

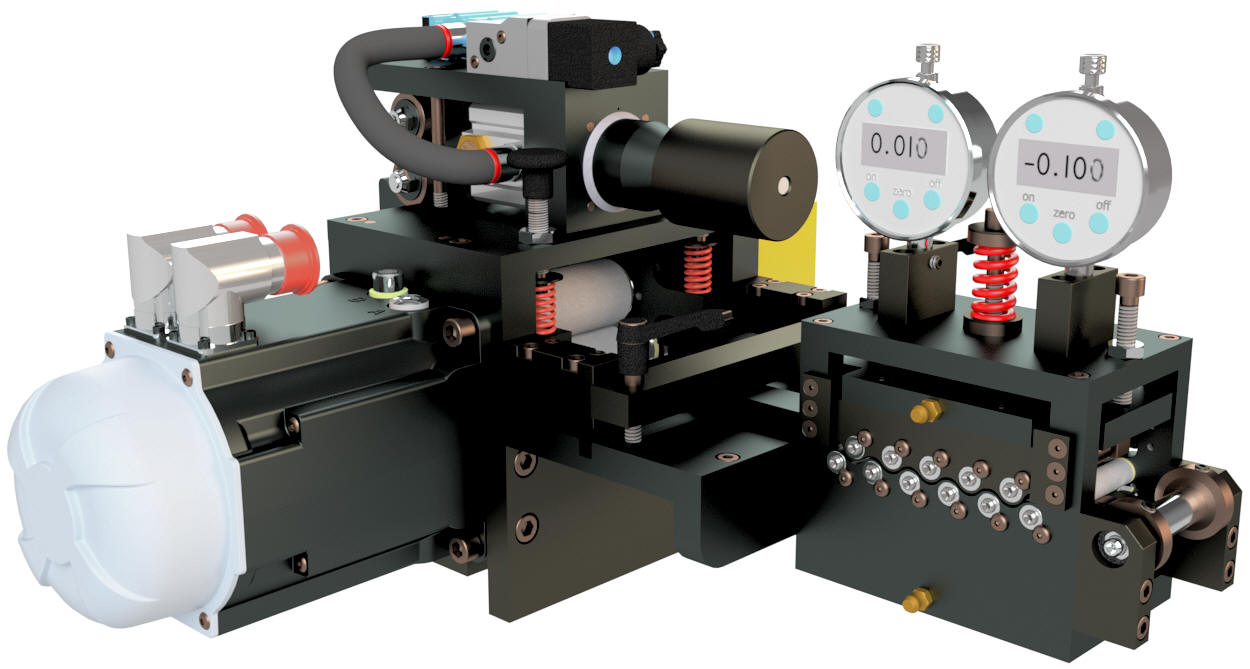

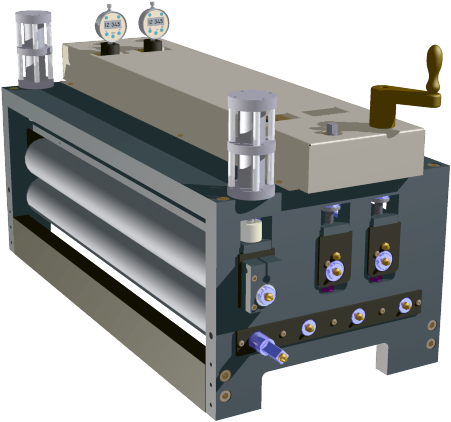

| Precision Micro Straightener |

2 inches wide 3/8 diameter rolls with backups Bank adjust. Dial or digital indicators for easy setting.    |

|

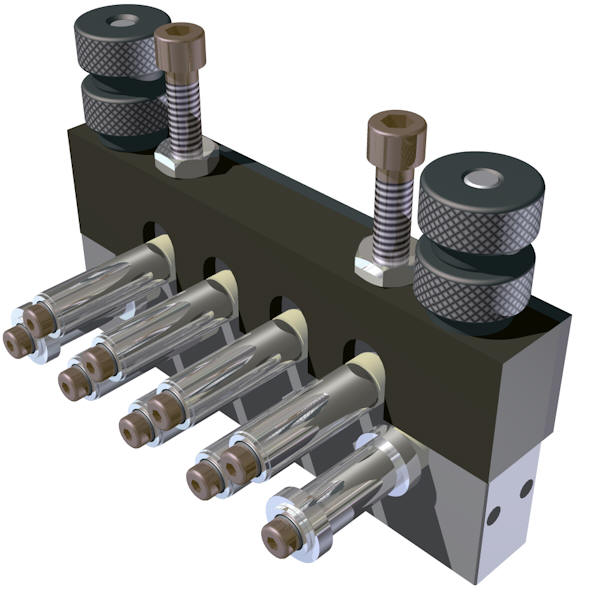

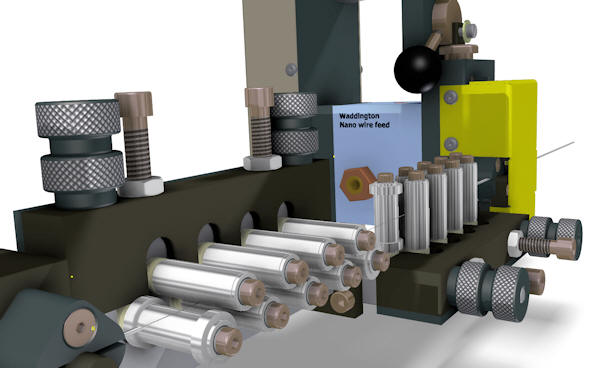

| Nano straighteners can be configured for wire or flat stock, foils, and other very thin materials. |

|

|

|

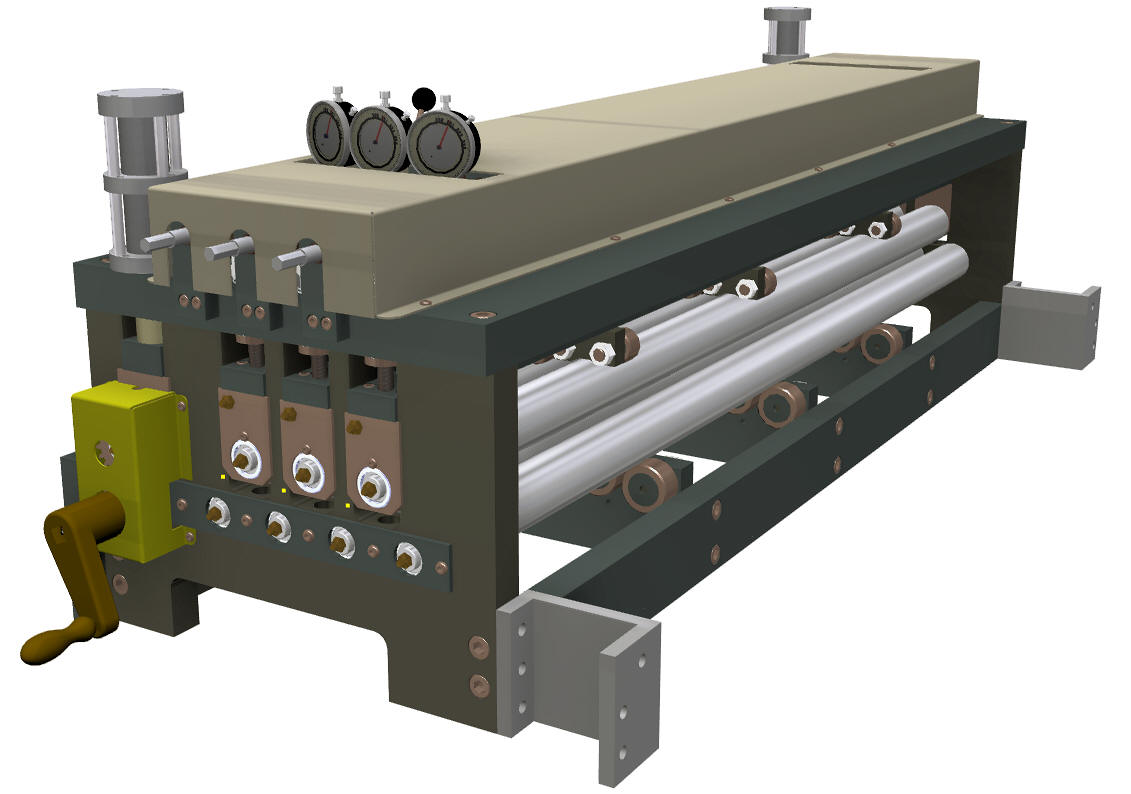

SFPT 1.25" diameter rolls 3 and 6 inches wide

The Waddington PT Series Tru-Trak Pull Through Straightener features 1 piece hardened and ground drive rolls with precision ground structural components, including side and top plates; square and parallel to track straight. Equipped with an entry set of pinch rolls for threading. Supplied for right or left hand feed applications, all moving members on this high reliability straightener incorporate anti-friction bearings |

|

|

| 5 and 7 rolls straighteners feature analog or digital indicators for fast repeatable setups |

|

|

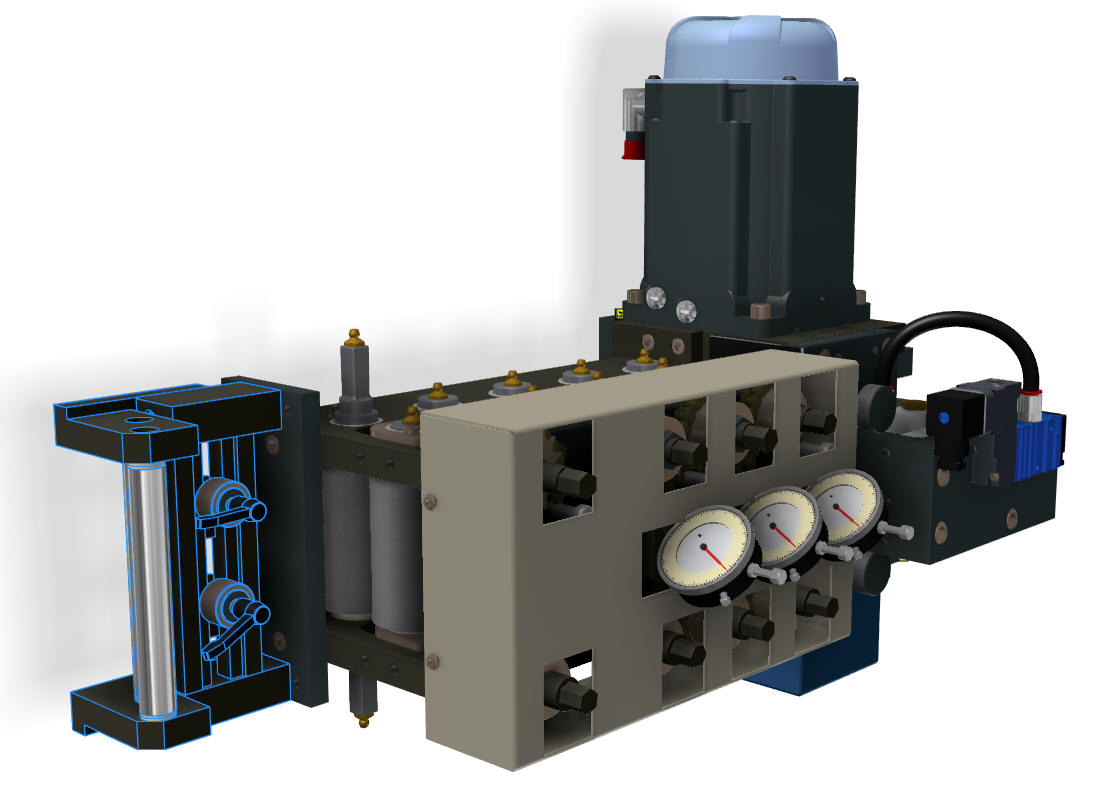

| LCPT01 3" diameter rolls from 12 to 48 inches wide with and without backups |

|

|

| Straighteners can be mounted in any

orientation this design is used on multislide machines. Where the coil is fed edge to the sky. |

|

|

| Wide straighteners

with small diameter rolls for thin materials require backup

rollers. This 48 wide machine features 3 sets. These rolls prevent roll deflection that would distort the material. |

|

|

Waddington Electronics Inc.

office 800-688-2645 - 417-864-3636

fax 417-864-3667