If there is something you need that you don't see please call us at 401-781-3904

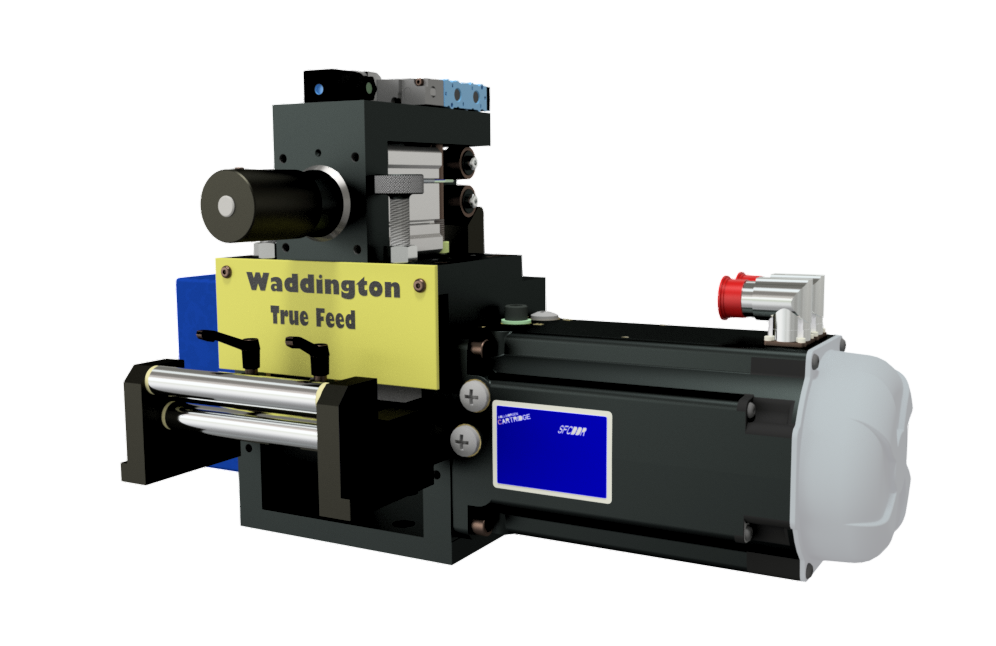

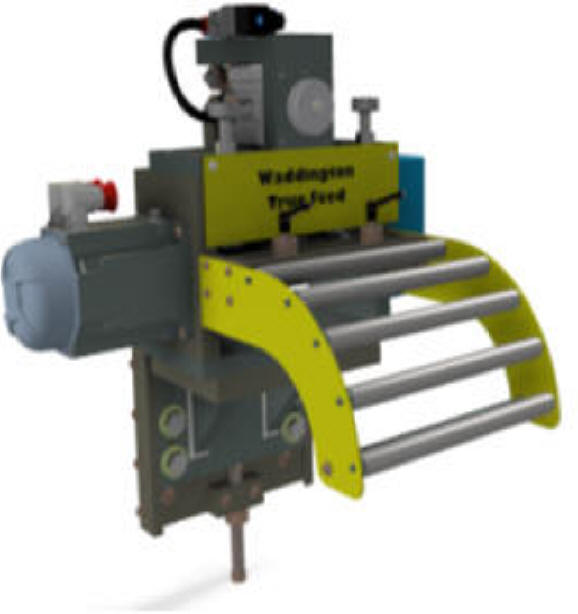

LD Direct Drive |

LD Direct Drive

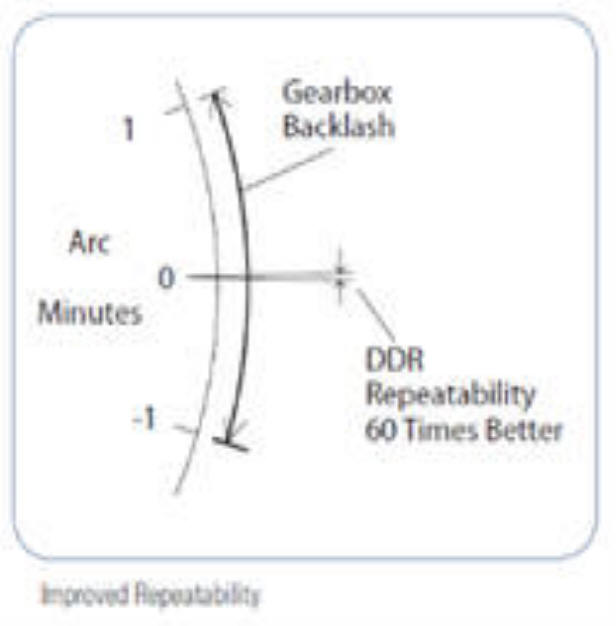

feeds perform better because they are better. Feeds with drive gearboxes have

backlash, even feeds with a really low backlash of 1 arc min

have 60 times more error than a direct drive feed. Direct drive feeds perform reliability

for billions of cycles with no change in accuracy or

repeatability. |

||

|

Very Fast Zero backlash and compliance provides more

responsive system performance Gears remain fully engaged through the entire feed thickness range. New controls feature touch screen user interface. |

||

|

|

Maximum Stock Width

3 to 25 inches |

||

| Mechanical Features: |

Two-inch diameter smooth steel finish rolls Our special low inertia

roll design is proven performer in thousands of applications. |

||

| Electrical Features: |

Available with |

||

| Compact feeds feature smaller motors and amplifiers than the standard feeds for applications that dont require the speed and power of our high speed machines |

|

||

PILOT RELEASE |

All feeds feature APR-3 the fastest

easiest to use pilot release you can buy. Customers are

running this pilot release at 400 SPM |

||

|

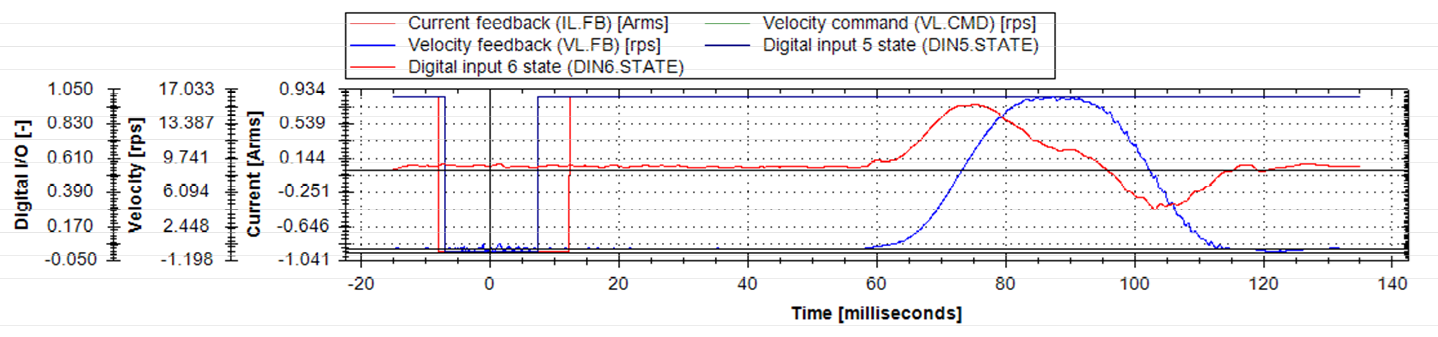

Included feed

software let you turn your laptop into a scope to perfectly

dial in pilot timing or other press or feed signals. |

|||

|

|||

|

Scope shows feed

velocity, current, pilot movement and pilot reference signal

from cam switch to check against actual pilot movement.

Optimizing pilot release timing lets you increase press

speeds and maximize production with confidence. Other

signals and sensors can also be viewed on the scope. |