Loop Controls

|

||

| Unruly loop controls cost you thousands of dollars in LOST PRODUCTION, SCRAP and TOOLING DAMAGE |

|

At Waddington electronics we tame loop control problems and regain control of your coil processing equipment. We offer a variety of loop control systems that can be tailored to your application. Proper loop controls can increase tooling life, eliminate damage to coil stock, relieve maintenance people to do real maintenance and keep your coil processing lines running smoother Dragging stock across the floor carries cement dust into your tooling, causing tooling wear and premature failure. Unstable and tight loops cause misfeeds and distortion of the stock. Starting and stopping of machinery causes material marking and uneven rewinding. Waddington loop controls increase profits and reduce down time!! |

|

|

Servo Loop for High speed stamping lines |

||

Waddington offers 4 major types of loop controls. |

||

| Super Dancer | Super Rugged Dancer arm with no potentiometer to wear out and electronic position adjustment, gain and integrator and derivative control terms | |

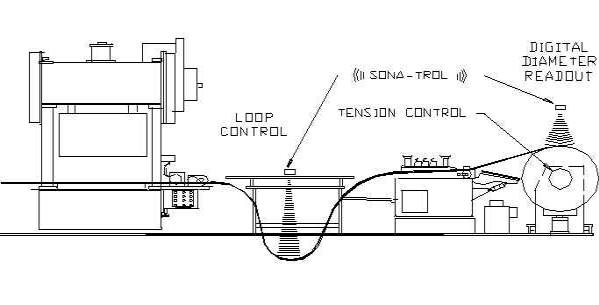

| Sona-Trol | An Ultrasonic based system, Sona-Trol controls free loops without contacting the material. The same system is used to measure roll diameters. Position loads in the space shuttle cargo bay and to monitor the first few inches of shuttle liftoff. | |

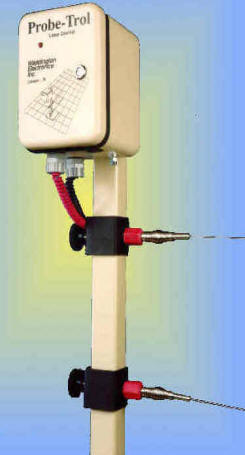

| Probe-Trol | Touch probes with a difference, Probe-Trol is a variable speed touch probe system that finds the line speed and gives ultra smooth payoff and take-up | |

| Photo-Trol | Works like our Probe-Trol but uses loop lights for control signals instead of touch probes. | |

Key Benefits

|